ASMPT chooses Renishaw for high-quality motion control

ASMPT is committed to the advancement of semiconductor assembly and packaging equipment and offers solutions for industrial automation in a wide range of semiconductor applications. It operates in over 30 countries with research centers, production facilities, and commercial offices spanning Asia, Europe, and the Americas. More recently, ASMPT expanded through a series of targeted business acquisitions, adding several equipment brands including ALSI, AMICRA, NEXX, and the AEi team. These acquisitions have enabled them to provide customers with a broader range of process solutions.

Renishaw’s relationship with ASMPT is now in its 25th year. Both companies have accumulated extensive shared experience in areas such as position encoder applications, customized solutions, and machine testing for quality control, while building a close business relationship.

Challenge

Modern semiconductor packaging and assembly processes require demanding performance in position accuracy and stability, machine size and weight, quality control, and process throughput. Position encoders play a crucial role in motion control, and suppliers need to develop new technologies and introduce innovative solutions to meet the rigorous demands of this market.

In the realm of assembly and packaging process equipment, selecting the right encoder is critical. ASMPT highlights several essential features that buyers should consider:

Solution

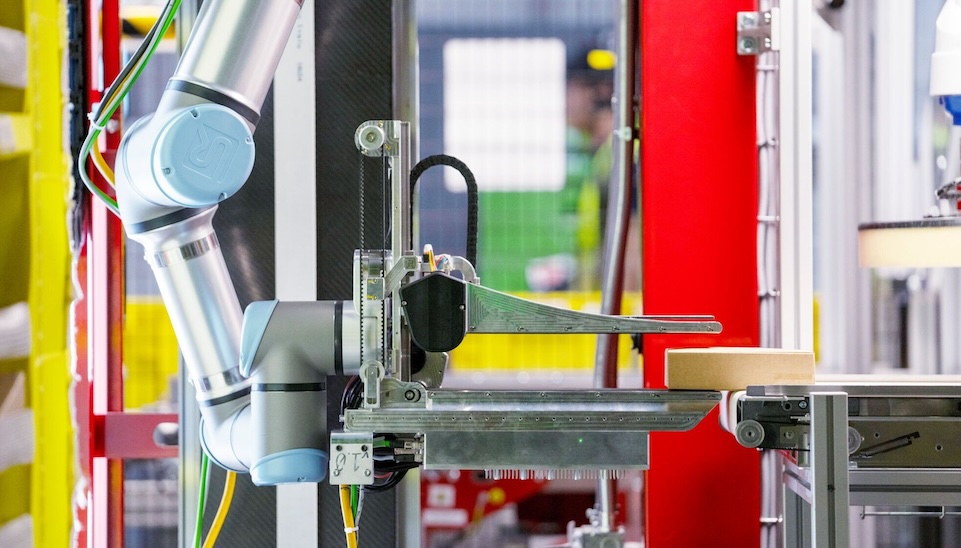

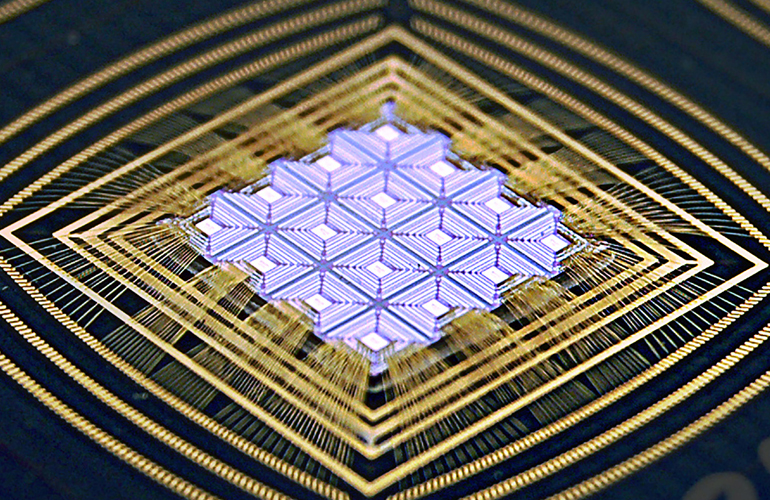

ASMPT has employed various Renishaw encoder products over the years including the ATOM DX and VIONiC incremental encoder series and the RESOLUTE absolute encoder series. These encoders are used in a wide range of assembly and packaging process equipment including ASMPT’s INFINITE — a 12-inch die bonder designed for general IC (integrated circuit) packaging. This advanced system boasts innovative features such as precise epoxy dispensing control and inspection capabilities for measuring bond line thickness with micron-level accuracy.

ASMPT’s INFINITE die bonding machine

As a crucial component in motion control systems, excellent encoder performance is fundamental to meeting the rigorous and increasing demands of the market. A prime example of an important encoder specification is the size of the readhead and interface. Back-end semiconductor manufacturing refers to the final processes, such as die bonding and wire bonding, after all the features on the silicon wafer have been created. Considering that back-end equipment can accommodate up to twenty readheads, it is essential to minimize the impact of the space occupied by these interfaces within the machine design.

“Given the application requirements of certain advanced packaging manufacturing equipment, it becomes imperative to utilize materials that exhibit less sensitivity to temperature for the working head; in other words, we need materials with a low thermal expansion coefficient,” explained Dr. Joseph Choy, Senior Research and Development Director at ASMPT. “However, these materials are typically heavier, which increases the overall equipment weight and introduces challenges in controlling inertia. Renishaw’s ATOM DX encoder series solves this problem and significantly reduces the space occupied and weight, while improving the flexibility of our equipment design process.”

Dr Joseph Choy, Senior Research and Development Director at ASMPT

The ATOM DX encoder directly outputs digital signals from the readhead and integrates all position feedback, onboard interpolation, and optical filtering functions within its miniature package. The readhead is designed to be extremely compact, with a minimum packaged size of 20.5 mm x 12.7 mm x 7.85 mm, allowing for installation in very small spaces without the need for additional connecting interfaces, saving significant space on ASMPT machines. The ATOM DX encoder series delivers excellent performance with a resolution of up to 2.5 nm and advantages such as low Sub-Divisional Error (SDE) and low signal jitter.

To streamline maintenance procedures, precision semiconductor manufacturing equipment often features a design that allows the cables to be detached from the encoder readheads within a module. These cables are then connected to the controller through an intermediary connector. This design enables swift replacement of the entire module in the event of a failure, minimizing downtime. Renishaw offers a range of encoder cables with different connector options for customers. These options include smaller-sized circular connectors or flying leads that can be soldered by the customer according to their specific requirements.

System diagnostics

Typically, the setup LED on the encoder readhead provides sufficient status information to ensure a successful installation. In more challenging installation scenarios, Renishaw’s Advanced Diagnostic Tool (ADT) can provide additional real-time data reporting, aiding installation and diagnostics. The ADT has thus played a pivotal role in ASMPT’s equipment development and production processes, particularly for its high-end equipment models.

“Renishaw’s ADT has been immensely helpful for us, allowing our engineers to quickly establish the installation status of encoders and identify the root cause of problems by assessing signal strength variations at different positions,” affirmed Ir George Chan, ASMPT Technical Manager.

Renishaw optical encoder range

Summary

The manufacture of assembly and packaging equipment faces significant challenges related to quality control and productivity.

Quality control is crucial in the manufacture of process equipment as it ensures specifications and reliability standards are met, guarantees process consistency, and helps to minimize defects and variation.

ASMPT has introduced new products designed to meet growing demand for semiconductors due to emerging technologies. Renishaw, a long-standing metrology supplier, offers extensive experience in quality control, encoders, and customized solutions. Encoder solutions include the ATOM DX miniature incremental encoder series, the VIONiC incremental encoder series, as well as the RESOLUTE absolute encoder series.

Renishaw’s Advanced Diagnostic Tool (ADT) and readhead setup LEDs also play an important role in encoder installation and diagnostics.

These metrology products ensure the optimum level of process equipment performance and efficiency.

Sponsored content by Renishaw