Gecko Robotics releases StratoSight drone-based roof inspection system

StratoSight marks Gecko Robotics’ first entry into aerial inspections and logistics. | Source: Gecko Robotics

Gecko Robotics Inc. recently released a new product with its partner, NAES Corp., called StratoSight. This latest offering from the robotics developer provides drone-based inspections for commercial roofs.

Jake Cornelius, the commercial director and chief technology officer at Gecko Robotics, spoke with The Robot Report about why the Boston-based company decided to automate roof inspections, the potential impact of the technology, and its plans.

“The thing that is common across all of Gecko’s offerings is basically the idea that to get the best solution, you need to be working end to end,” he said. “It’s really the integration of robotics, software, and humans, both on the data-collection side, but then also on the interpretation of that data to make the right decision. The best outcomes are unlocked when you string that whole value chain together.”

This end-to-end approach has been Gecko’s focus from Day 1, when it was primarily focused on automating boiler inspections, said Cornelius. This focus is what led the company to hone in on roof inspections with its latest offering.

A problem sitting right above our heads

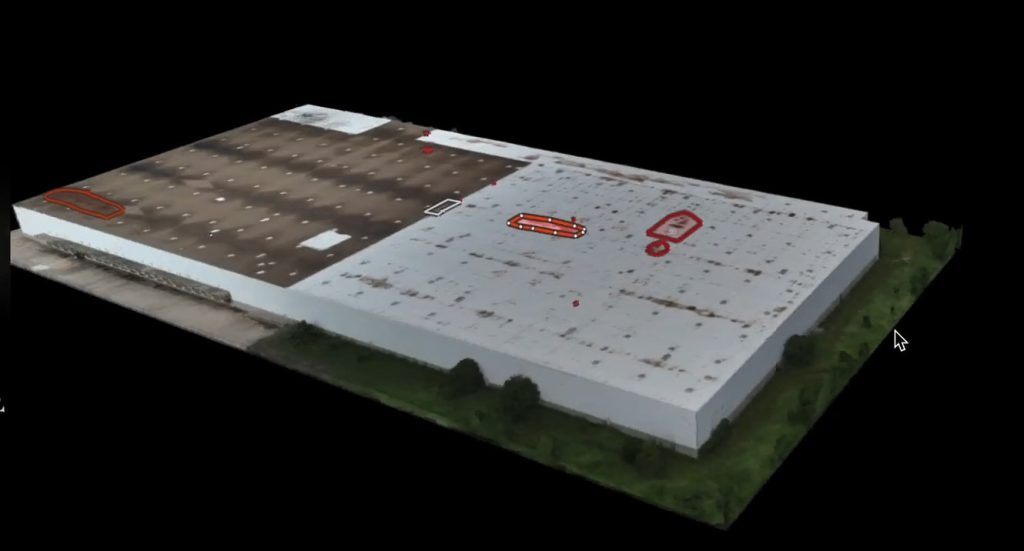

StratoSight can detect early signs of degradation like thermal loss, water intrusion, and structural shifts before they escalate. | Source: Gecko Robotics

Cornelius said he was surprised to learn how big a problem commercial rooftop inspections are in the U.S. “There are billions of square feet of commercial rooftop in the country, and we heard time and time again from people who manage these facilities, ‘The most dangerous thing I do is put people up on this roof to inspect it,’” he said.

These inspections are also not very effective. Human roof inspections will miss around 50% of critical issues. “There are cases where, if you just have a tiny nick on a roof membrane, it could cause a massive problem. If water gets in, you start to have a moisture containment issue,” Cornelius said.

Once Gecko Robotics understood the size of the issue, it recognized a prime opportunity for automation.

“There are a lot of good drone platforms out in the market. We don’t seek to reinvent the wheel, so we did not build our own drone,” Cornelius said. “We use stuff that’s off the shelf and modify that for our purposes as we seek to solve the customer problem.”

“The offering, as it currently stands, basically has a custom payload that sits on top of a drone. It collects high-definition photogrammetry at a very high level, and then thermography at a high level,” he continued. “There are some other payloads we’re experimenting with that will be able to detect new — we call them ‘data layers’ internally — but new sources of data and new inputs that we’ll be able to use to help inform customers’ decisions.”

StatoSight helps make the most of crucial data

While the StratoSight hardware is an important aspect of the system, Cornelius said he is most excited about Gecko Robotics’ advances in data processing.

“Anyone can get a drone up and fly it. The question is, how do you turn that data around in a way that is timely enough for a commercial customer?” he said. “So, it’s really this integration of the payload that we customized, along with the software architecture that facilitates not just the processing, but [also] the platform allows you to do automated defect detection.”

The system does the bulk of its processing in the cloud, Cornelius said. So the robot will go up onto a roof, gather data, and send all of that back to a “mothership,” which will evaluate the data and give it back to the customer.

With manual inspections, a facility manager would send a person to the roof, who would document any issues they notice. “Then what you get is this 80-page PDF with just a bunch of photos and maybe a written description of here’s where this thing is,” Cornelius noted. “It actually doesn’t help you that much, because now you’ve got to go back up on the roof and try to find where this image is on your million square feet of roof.”

With Gecko, customers can more easily make sense of the data they get, and more easily identify where repairs are needed, he said. An end user can simply log in to Gecko’s system, look at the facility, and identify which spots in the model need attention, explained Cornelius.

Gecko dips its toes in logistics spaces

“One of the things we’re most excited about is the next step for these facilities we traditionally haven’t worked in,” Cornelius said. “We’re more on the industrial side, so getting into a lot of warehousing and logistics, that’s a market we’re really excited about.”

At the same time, logistics is a massive market with many big players, so Gecko knows it needs to be ready to scale with its customers. “It’s not good enough to be able to just put a drone up in a small geography; you need to be able to do this nationwide, because the people with the biggest problems are nationwide operators,” Cornelius said.

This is where its partner, NAES, has been particularly helpful. Cornelius said the NAES team already has experience with scaling. The Issaquah, Wash.-based company already has a lot of partners in the logistics space.

Looking ahead, Gecko sees these as the first step in its journey with new types of facilities. Even just with inspection, there are a lot of things on roofs, including photovoltaic cells, HVAC (heating, ventilation, and air conditioning) systems, and fire-suppression systems. Some customers have told Gecko Robotics that they are interested in StratoSight because they want accurate building drawings.

“If you really understand the condition of commercial rooftops in America, there are some unique workflows you can build on top of that. So, I’m really excited about that,” Cornelius said.