Why automation is the medicine that hospitals and the healthcare system needs

Hospitals are increasingly using mobile robots to move materials and relieve worker strain. Source: Cleveland Clinic

Hospitals are wrestling with workforce shortages, aging infrastructure, and a financial model stretched to its limits. The American Hospital Association projects that the U.S. will face a shortage of up to 124,000 physicians by 2033. At least 200,000 nurses must be hired per year to meet increased demand and to replace retiring nurses.

The math doesn’t add up unless we change the equation.

The answer may lie not in more people, but in smarter systems. Automation, robotics, and artificial intelligence are quietly reshaping how hospitals move, manage, and deliver care. And if the manufacturing sector’s transformation is any indication, healthcare’s next leap forward will come from the machines working behind the scenes.

The new anatomy of smart hospitals

Every hospital depends on logistics — the unseen flow of supplies, medications, and equipment that keeps everything running. When that system falters, clinicians are left waiting, patients are delayed, and costs spiral.

Tecsys research has found that 15% to 20% of a nurse’s time is spent managing inventory rather than providing direct patient care. That’s a staggering inefficiency in a system already stretched thin.

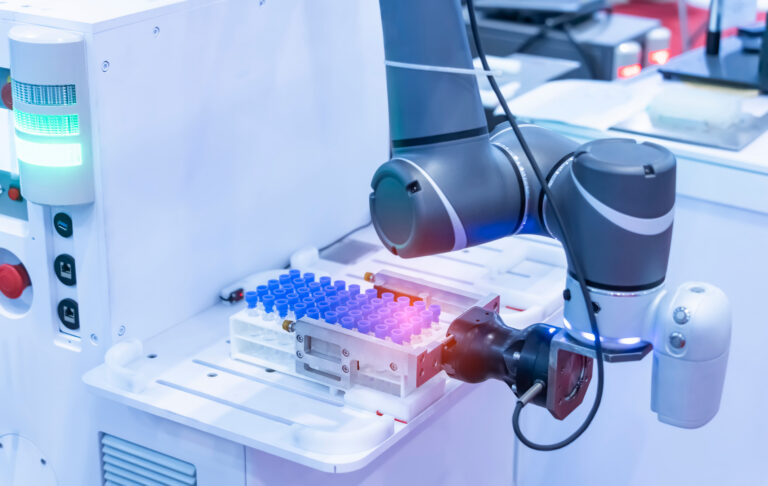

Automated guided vehicles (AGVs), autonomous mobile robots (AMRs), and AI-driven inventory systems are transforming how hospitals operate — quietly, efficiently, and relentlessly. Robots now carry linens, meals, and medications across facility floors; AI predicts when supplies will run low; digital twins simulate hospital flow to prevent bottlenecks before they happen.

For example, at Cleveland Clinic and Cedars-Sinai, fleets of robots handle routine deliveries, freeing nurses to focus on patients. The results? Faster turnaround, lower labor costs, and higher staff satisfaction.

Cleveland Clinic handles materials with AGVs

Cleveland Clinic has implemented one of the most advanced hospital logistics robotics systems in the U.S., using AGVs to streamline the movement of goods across its main campus and service centers.

The Schachinger Group evaluated several material-handling options, including manual transport methods, electric tugs and carts, platform vehicles, AGVs, and other robots to determine the best solution for moving materials between Cleveland Clinic’s main campus and its service center.

Based on the study’s findings, it selected AGVs. The system includes 81 self-driving transport units and more than 1,000 carts, together performing about 4,800 cart movements required to support the hospital’s planned 1,400-bed capacity.

Each day, the AGVs collectively travel over 1,000 miles while moving a wide range of materials, including clean and soiled items such as linens, supplies, waste, meals, sterile instruments, pharmaceuticals, and medical equipment.

By automating routine transport tasks, Cleveland Clinic said it has freed staffers to focus on patient care while improving hygiene and workflow consistency. The robotics program became an integral part of the clinic’s supply chain and facilities operations, serving as a model for large-scale hospital automation.

The Cleveland Clinic stocks about 3,000 SKUs and manages up to 100,000 more non-stock items. Source: Schachinger Group

Cedars-Sinai uses a combination of mobile robots

Cedars-Sinai Medical Center has also embraced automated material transport systems through a combination of AGVs and AMRs. A fleet of nearly 28 robots, including systems from Diligent Robotics and FMC Technologies (which is now part of JBT Corp.), move about the halls of Cedars-Sinai 24 hours a day.

Weighing around 1,000 lb. (453.5 kg) each, the vehicles travel through dedicated elevators, corridors, and service levels within the hospital towers, transporting up to 20 tons of surgical supplies, linens, food, and waste each day. The robots’ routes are designed to minimize contact with human workers, but they are also equipped to interact safely with people when needed.

The hospital also advertises dedicated roles in logistics for its AGV system, which handles surgical case carts, soiled linen streams and biohazardous waste across multiple buildings. Cedars-Sinai’s system demonstrates how large healthcare facilities can integrate robotics into their internal logistics to improve efficiency, staff satisfaction, and operational throughput.

Cedars-Sinai is using AGVs and AMRs for internal logistics. Source: Cedars-Sinai Medical Center

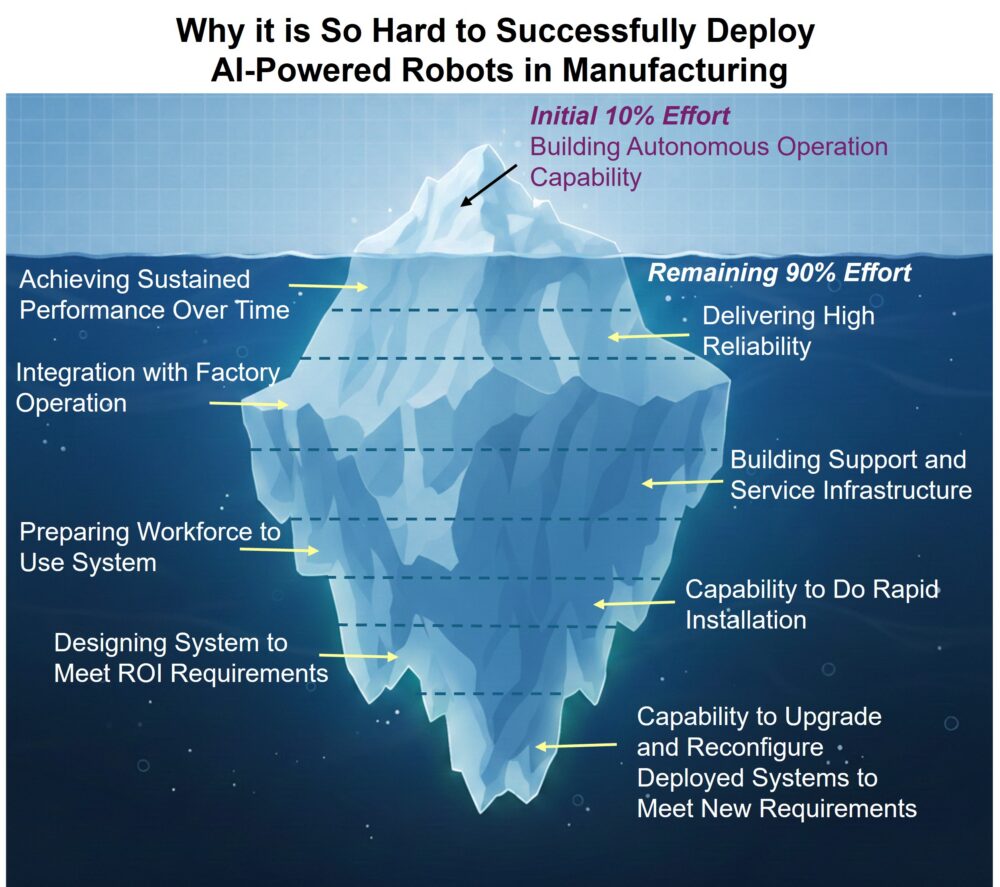

Lessons for hospitals from the factory floor

This isn’t the first time robots have rewritten the rules. In U.S. manufacturing, automation has long been the backbone of productivity and according to the latest World Robotics report, 381,964 industrial robots are currently operating in American factories.

Now, those same principles — precision, consistency, and scalability — are making their way into healthcare. What AGVs and AMRs once achieved on assembly lines, AI-enabled robots are now bringing to hospitals. They are taking on repetitive, predictable, and high-stakes tasks that demand machine-level reliability.

And this isn’t about replacing workers; it’s about redefining the way work gets done.

More intelligence goes inside the machines

The real leap isn’t just robotics but AI working with robotics hardware. AI gives machines the ability to learn, adapt, and make context-driven decisions.

Picture robots that navigate crowded hospital hallways, adjust routes on the fly, and predict where they’re needed next. AI enables that through computer vision, machine learning, and predictive analytics. These smart systems can:

Forecast supply usage based on patient admissions and case types

Identify inefficiencies before they become disruptions

Learn from human workflows and adjust automatically

What we’re witnessing is the rise of intelligent automation — a partnership where humans and machines co-create efficiency, not compete for it.

Hospitals can boost sustainability, scalability, and human impact

Automation is also proving to be a sustainability strategy. According to the National Academy of Medicine, the health sector accounts for approximately 8.5% of U.S. greenhouse gas emissions, and hospital care makes up the greatest portion of the sector’s emissions — much of it from waste and inefficient supply chains.

Smarter systems can reduce overstocking, minimize expired medications, and cut transport emissions through route optimization.

At the same time, freeing staff from manual tasks has a measurable human impact. McKinsey estimates that a net 10% to 20% of time spent during a 12-hour shift is spent on activities that could be optimized through tech enablement, giving care teams more time for patients.

That’s not just operational efficiency, that’s emotional efficiency.

The road ahead: Automation with a human heart

The U.S. healthcare system doesn’t need added complexity, it needs more clarity. Systems that think, move, and adapt in step with the humans they support are the key to making that vision a reality.

Robotics and AI won’t cure the workforce shortage overnight, but they can redefine what’s possible, creating hospitals that are not just smart, but self-optimizing; not just efficient, but sustainable.

We’ve already seen this scenario in manufacturing. The question isn’t whether automation will transform healthcare; it’s how fast it will do so. The future of care won’t just be human; it’ll be human and machine working in perfect sync.

About the author

Diana Davoyan is a marketing professional and copywriter in the global robotics sector, with extensive experience in industrial and warehouse robotics.

She crafts thought leadership and trend-driven content that turns complex automation technology into clear, engaging insights. Passionate about the intersection of innovation and communication, Davoyan highlights emerging trends, shares industry expertise, and helps audiences grasp the transformative impact of robotics and automation across logistics and manufacturing.