Transforming solar farms: AI, robotics, and industry partnerships at AES

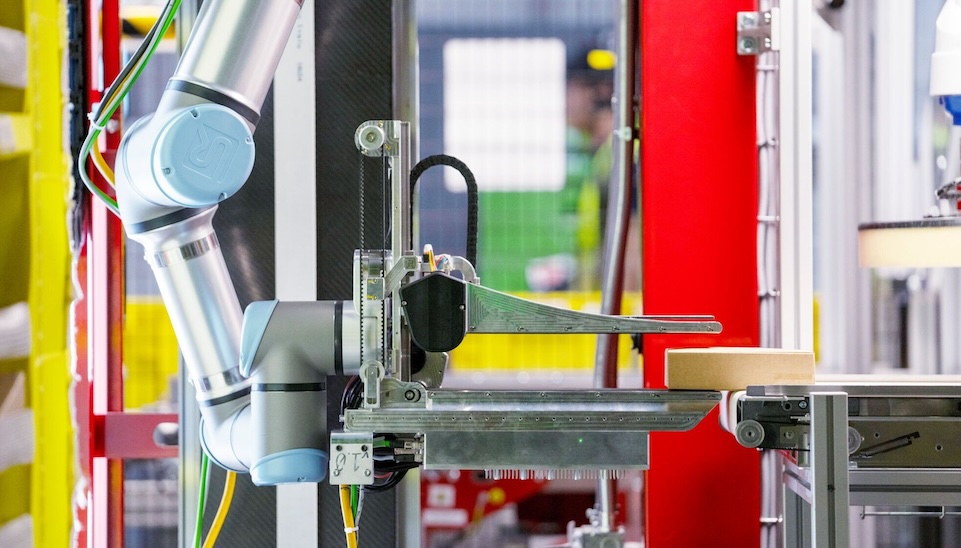

Maximo automated solar panel installation, leveraging the quality and precision of an industrial robot mounted on a mobile chassis. | Credit AES

The Robot Report recently sat down with Chris Shelton, the SVP and chief product officer at AES, to discuss AES’s transition from power generation to clean energy, focusing on solar construction. AES developed Maximo, a solar construction robotics service, leveraging AI vision, industrial robotics, and a mobile microgrid system.

Maximo, first introduced in 2024, autonomously installs solar panels, with a fleet of four robots currently assembling 1 megawatt per day, equivalent to 1,900 panels. The company also plans to integrate Maximo with EPC companies and develop an intelligent planning platform for the robots.

AES is on its fourth generation of field-tested robots

AES expects version four of Maximo to be in the market in Q2 of next year. The solution is centered around an industrial six-axis robot arm, mounted on top of a mobile platform. A second, smaller industrial arm is mounted on the side of the platform, and designed to reach under the panels to complete the attachment process. The robots are powered from onboard batteries and leverage vision and lidar sensors to track the precise locations of the panels, the panel mounts, and the surrounding crew.

The mobile platform is not autonomous in this generation of the platform, but is towed by a tractor. The company expects to make the platform autonomous in a future generation.

The panel installation is delivered as a service according to Shelton, “Maximo is a solar construction robotics service that uses the robotics solution we provide; we get paid for an installed module. So we’re going to market with the whole solution, not just the technology. We think that’s the right approach for our industry. Maximo serves engineering, procurement, and construction companies that build solar farms for AES and others.”

“We’re just doing the physical part where we’re getting it out of the box and placing it on the torque tube, and attaching it on the bottom right. So that’s just highly repetitive,” Shelton continued, “a crew would install 250 to 300 of those per day in desert heat. And those are about 80 pounds each.”

The operating environment for the Maximo system is harsh. When asked about the technology at the heart of the system, Shelton stated, “We thought AI and robotics were a good fit, and we bet on several trends. One of the biggest bets was on AI-based vision. We expect to have different lighting conditions and different weather. We’ll have different module sizes, different module manufacturers, and different mounting styles. So we bet on vision being able to deal with that. The second element is to use proven industrial robotics for the assembly process. The robots are sealed against the elements and designed to last.”

Solar will support growing data center needs

In California, AES is building the largest solar storage complex in the United States for Amazon. All of the power will go to Amazon datacenters. It’s 1000 megawatts of solar and 1000 megawatts of batteries. Maximo is building about 15% of phase two of that. According to Shelton, the company should be done with the installation by the end of December.

Responses