iREX 2025: From programmed to perceptive

iREX 2025 was held in Tokyo from Dec. 3 to 6. Credit: Georg Stieler

The International Robot Exhibition, or iREX 2025, earlier this month set new records: 673 exhibitors and 156,110 visitors — even with parts of the Tokyo Big Sight exhibition ground under renovation.

The mood at the event was good, as market order intake is recovering after two years of decline (particularly driven by exports). What did I see there that I haven’t seen somewhere else before?

1. Practical AI: From lab to factory floor

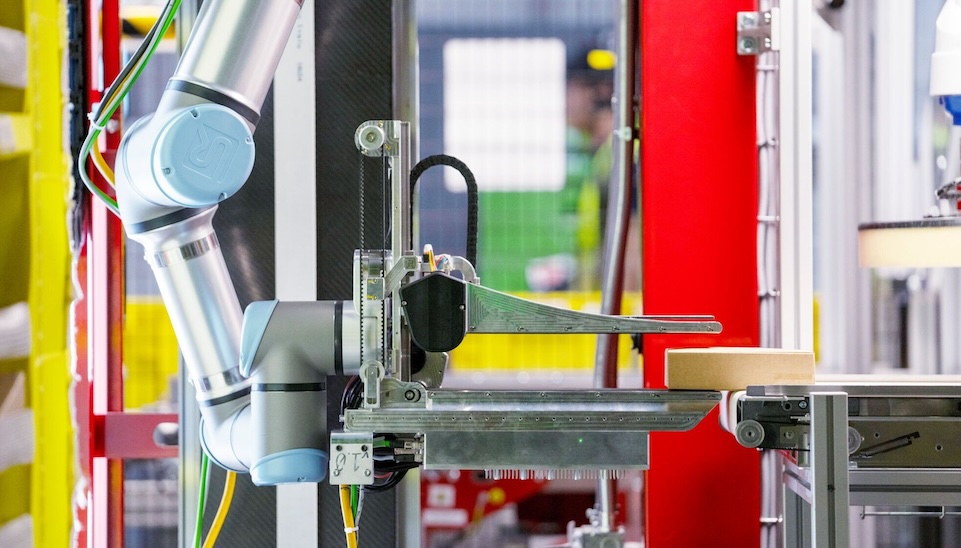

While there were plenty of dancing humanoid robots, primarily of Chinese origin, what caught my eye were AI-enabled industrial robots to handle the slight variations and complexities previously reserved for human dexterity.

For example, Yaskawa showed the MOTOMAN NEXT-NHC 10DE, an autonomous dual-arm robot that packs items into a box with human-like delicacy.

According to Yaskawa, the robot’s motions were learned by imitation of a human demonstration. Engineers first had a person wear motion-capture markers on their hands and recorded the person carefully packing a box on camera. Using this captured data, the NEXT-NHC 10DE replicated the human’s packing motions.

Yaskawa’s iREX exhibit emphasized AI controls (developed with NVIDIA) for adaptive, precise dual-arm coordination. This means the robot wasn’t just pre-programmed; it used AI algorithms running on a high-performance GPU to perform real-time adjustments, such as visual inspection of item placement and gentle handling.

The MOTOMAN NEXT-NEX35 is capable of unloading, unpacking, and feeding variable raw materials. This system has an autonomous control unit and fuses AI judgment with robotics, enabling real-time recognition and decision making as surroundings change.

We had advised a beverage manufacturer with similar needs about its automation strategy six years ago, but they were impossible to meet at that time.

2. Platform play: Opening up the walled gardens

Closely related to AI was FANUC’s surprising pivot to more openness. Historically known for closed, proprietary robot controllers, Japan’s largest robot manufacturer announced a strategic partnership with NVIDIA to accelerate physical AI in industrial robotics just before iREX.

FANUC released a ROS 2 driver on GitHub, allowing developers to control its robots via the open-source Robot Operating System. The company also introduced official Python and ROS 2 support on its latest controllers.

This open-platform approach is meant to “enhance connectivity with external AI environments” and speed up implementation of physical AI – essentially connecting robot arms with modern AI software. FANUC’s ROS 2 driver supports 1-millisecond control loops and works across models, from small cobots to its 2.3-ton heavy robot.

The driver still depends on specific FANUC controller software options (J519/R912 or S636), so this openness is focused on developer workflows, while key controller capabilities remain licensed. Furthermore, FANUC integrated NVIDIA’s Isaac Sim simulation platform, contributing official 3D models of its robots for virtual testing and AI training.

At iREX, FANUC demonstrated a AI-powered dual-arm cable installation system with Japanese AI startup Fingervision, as well as a collaboration with Inbolt from France for tracking and working on moving parts (see video below). It also showed a robot responding to and executing natural language voice commands.

It is fascinating to see that applications that were experimental five years ago are now so stable that they are becoming mainstream.

The trend toward more openness was also reflected by Kawasaki’s introduction of its “open” controller concept. A single controller synchronously controlled two force- and power-limited or collaborative robots from Kawasaki, an electric gripper from Oriental Motor, and the XPlanar magnetic floating linear conveyor system from Beckhoff Automation.

Kawasaki further showed the advances of its ROBO CROSS cloud platform, where end users can download applications and tools developed by system integrators as modules. Participating companies so far include Kawasaki Heavy Industries, NTT Business Solutions, Daihen, FingerVision, Yasukawa Electric, Yamaha Motor, and Japanese startup ugo.

Whereas these moves are necessary to accelerate innovation security, these strategies also pose new challenges. Security, stability, and AI concentration are risks as advanced AI access is increasingly becoming dependent on a small set of suppliers — notably NVIDIA — with corresponding bargaining-power implications.

The winning robotics companies probably won’t be the most “open” or “closed” but the ones that define a clear differentiation layer: application libraries, high-quality task data, validated safety, and lifecycle support.

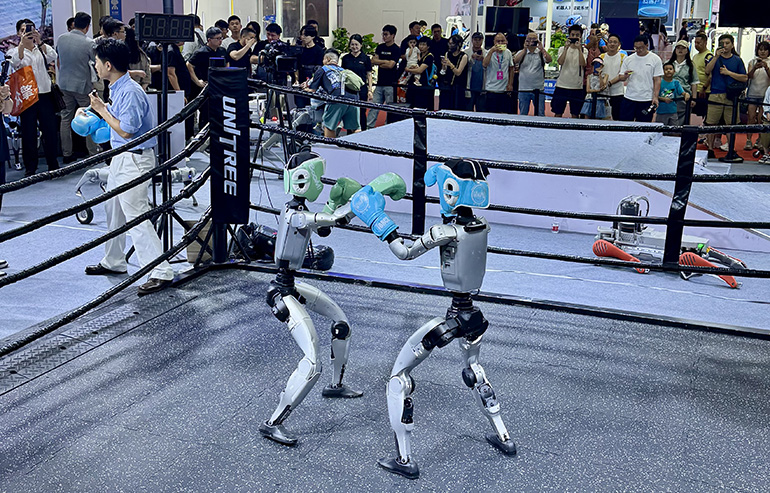

3. Chinese players continue international expansion at iREX

Chinese firms turned out in force, with 84 exhibitors (up from 50 in 2023) making up the majority of overseas companies at iREX 2025. Such high-profile events are an important platform for them to present themselves not only to a Japanese, but also to an international audience.

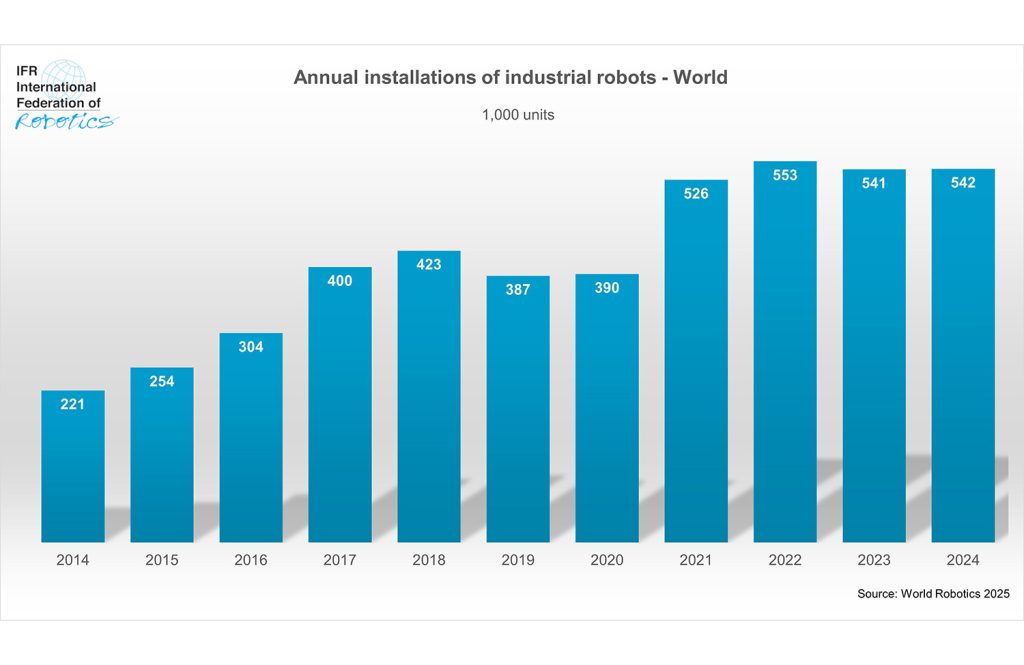

While we haven’t yet seen Chinese industrial robots making inroads in Japan, they have become formidable competitors in other parts of the world. Back in 2016, Japan controlled roughly a third of global robot exports. By 2024, its share had slipped to around 21%, while China’s share climbed from about 3% to 4% to nearly 10%.

At iREX, the most visible Chinese exhibitors came from segments where Japanese players are less visible or less aggressive on price – low-cost cobots, humanoid robots, and advanced tactile sensing. Their strategies differ. For instance, Dobot has started to hire more local staffers, which seems like the right approach, as this enables it to poach more top talent in local markets such as the U.S. and Japan.

Physical AI will require a lot of real-world data. A growing share of the hardware used to collect that data – especially low-cost sensing and humanoids – is coming from China. PaXini showed its PMEC Hyper Collection System, consisting of a camera and gloves with multidimensional tactile sensors.

AgiBot, one of China’s leading humanoid robot makers, used iREX to announce its entry into the Japanese market and showed its vision-language-action (VLA) model ViLLA.

4. European deep-tech startups scale through globalization

It was encouraging to see European deep-tech startups presenting themselves in Tokyo. The aforementioned Inbolt showed applications at the booths of both FANUC and Universal Robots (UR).

Swiss startup AICA showed an AI-powered gearbox assembly with partner UR. Even though they’re still young, the path to scale for these companies is through global partnerships with major manufacturers in the U.S., Japan, and South Korea.

5. iREX 2025 gives a glimpse into the future

One of my favorite exhibits at iREX came from SOLOMON, a machine vision specialist from Taiwan.

It tuned a Unitree G1 humanoid with enhanced, more capable hands and an onboard NVIDIA Jetson AGX computer. Using NVIDIA’s GR00T platform, the robot was trained to see up to 5 m (16.4 ft.), understand orders in natural language, and plan the physical steps to pick from a defined set of objects.

The application was still shaky and did sometimes have trouble grasping the objects at the first attempt, but it provided a glimpse into the future. A ChatGPT-style moment for embodied intelligence — when robots will be able to generalize natural-language instructions to new, non-preprogrammed tasks — seems possible in the not-too-distant future.

About the author

Credit: Georg Stieler

Georg Stieler advises some of the world’s largest robotics companies. He spent more than 10 years living in China and now splits his time between Switzerland and the People’s Republic of China.

Thanks to multi‑year, close collaboration with AI startups in Silicon Valley, Stieler is also deeply familiar with its culture.

Responses