A national robotics strategy is necessary to reshore manufacturing, says the Congressional Robotics Caucus

Rep. Jay Obernolte, co-chair of the Congressional Robotics Caucus, addresses a meeting in the Rayburn House Office Building. Credit: DLA Piper

WASHINGTON, D.C. — The U.S. needs robots and workforce development to successfully reshore production, said members of the Congressional Robotics Caucus at an event organized by the Association for Advancing Automation (A3) and law firm DLA Piper this week.

The U.S. needs a unified federal approach to robotics and skills development to be competitive, asserted Jeff Burnstein, president of A3. He also introduced a panel on “The Key to Reshoring Manufacturing: A Skilled Workforce, Advanced Robotics, and a National Strategy.”

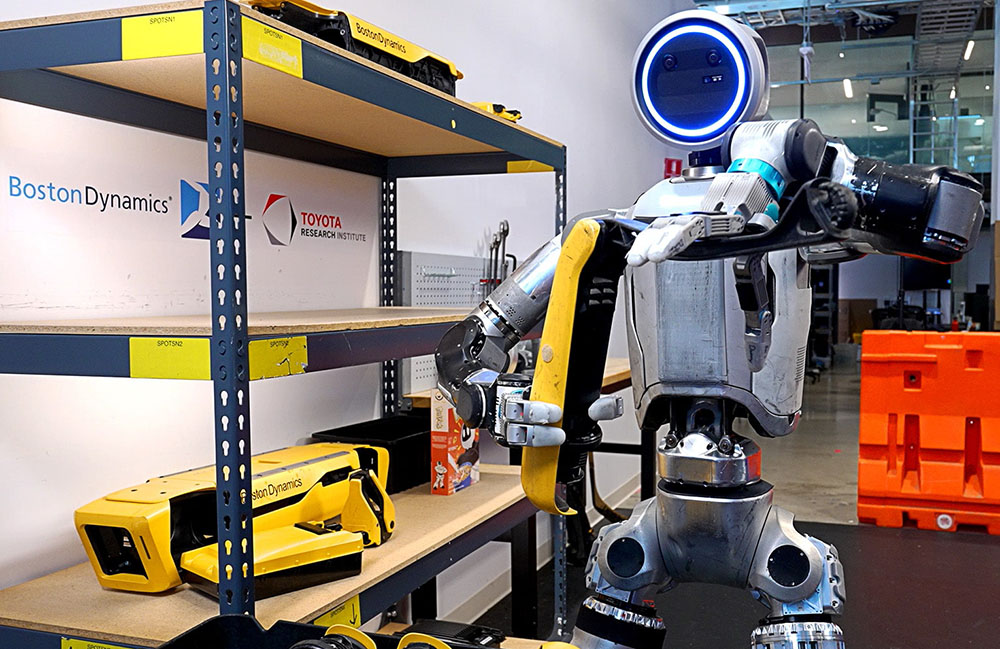

Exhibitors at the event included ABB Robotics, Boston Dynamics, FANUC, General Robotics, Intrinsic, Path Robotics, and Standard Bots, as well as Lorain County Community College (LCCC). Attendees included representatives of robotics vendors and staffers from other congresspeople‘s offices.

Sector needs national attention, says Congressional Robotics Caucus

The Congressional Robotics Caucus was founded in 2007, but the advisory committee did not meet from 2019 to 2025. In May, it relaunched with plans to educate the U.S. House of Representatives and Congress as a whole about the vital role that automation can play in U.S. competitiveness.

Rep. Jim McGovern (D-MA), co-chair of the Congressional Robotics Caucus, noted that while his district includes Worcester Polytechnic Institute (WPI) and Clark University, it and the nation still have problems with the erosion of manufacturing, workers’ rights, offshoring, and affordability.

“Only with strong leadership from many sectors will we be successful,” he said, adding that government, industry, and academia all have roles to play.

McGovern acknowledged that artificial intelligence has gotten more attention lately than robotics, with Democratic Leader Hakeem Jeffries launching a House Democratic Commission on AI and the Innovation Economy. President Donald J. Trump this week signed an executive order to create a U.S. Department of Justice task force to investigate state AI laws and create a national AI framework.

Rep. Bob Latta (R-OH) added that his district in Northern Ohio, near the Indiana border, has 86,000 manufacturing jobs. Most U.S. manufacturers are small and midsize businesses (SMBs), according to the National Association of Manufacturers.

“We learned tough lessons in COVID,” he said. “The supply chain was a disaster, and we realized the need to reshore. We’re in a global competition with communist China, and there are no medals for second place.”

Reshoring manufacturing is critical to both economic and national security, added Rep. Jay Obernolte (R-CA). “There’s a misperception that robotics leads to a loss of jobs,” he said. “Technology is disruptive, but it always results in more jobs — just different jobs. We need to equip the workforce with the right skill sets.”

“We need a national strategy,” said Obernolte. “That’s why we have this caucus — to evangelize.”

Boston Dynamics’ Spot, a quadruped used for industrial inspection, was among the exhibits at the Congressional Robotics Caucus meeting. Credit: Eugene Demaitre

Education to shape industry fortunes, according to panelists

While the $1.2 trillion bipartisan infrastructure bill helped utility manufacturing, lead times on transformers, a key technology, went from 20 months to five years because skilled labor can’t keep up with the surge in demand, noted Heather Carroll, chief revenue officer of Path Robotics, which provides automated welding systems.

With 157,000 welders approach retirement and 80% of welding still being manual, the utility, shipbuilding, and other industries need government help aligning education with their needs, said Carroll.

Rep. Latta recalled a recent visit to a career center, where he spoke with a 17-year-old who was interested in training others to work with robotics.

“With Lorain County training, people can get good-paying jobs right out of school,” Latta said. “For anybody graduating high school, college, or with an advanced degree, if you think you’re done with learning, you’re already behind.”

There are plenty of state workforce initiatives, but they need to scale, said Terri Sandu, director of talent and business innovation at LCCC and director of Ohio TechNet. She recommended that the government make clearer what agencies and programs can help SMBs with robotics and AI. Sandu cited resources such as the ARM Institute‘s RoboticsCareer.org.

Jason Moore, a Regional Advanced Manufacturing & Engineering Technology Education Center (RAMTEC) instructor at the Mahoning County Career and Technical Center (MCCTC), and Matt Peters, a technical integrator at the MCCTC in Ohio, gave examples of how robotics technicians can get certified, providing career pathways at a fraction of the cost of traditional colleges.

Ashish Kapoor, co-founder and CEO of General Robotics, noted that there are not enough robotics programming experts. “Only 1 in 10 machine learning engineers works on models for robotics,” he said. “Large teams are collecting data and using GPUs, but there’s a lack of concentration on AI-centric building of robots, which requires stronger STEM pipelines.”

Jeff Burnstein, president of A3, introduced the panel discussion, which included, from left, Boston Dynamics’ Brendan Schulman, Path Robotics’ Heather Carroll, Intrinsic’s Torsten Kroger, LCCC’s Terri Santu, and MCCTC’s Jason Moore and Matt Peters. Credit: Eugene Demaitre

Federal focus is more important than funding

Boston Dynamics has been working with Washington for the past year or two, according to Brendan Schulman, vice president of policy and government relations at the legged and logistics robot company. CEO Robert Playter recently said he has been talking with U.S. Secretary of Commerce Howard Lutnik about a national robotics strategy.

“We’ve had decades of robot arms deterministically programmed for factories,” Schulman observed. “With reinforcement learning, large models, and behavioral data, we can now accelerate development, not just for manufacturing, but also for healthcare, defense, and other sectors.”

“More money alone doesn’t solve the problem,” asserted Carroll. She said capex incentives don’t take into account robotics-as-a-service (RaaS) models. In addition, the U.S. should address permitting bottlenecks and support national-level standards.

“It’s important to harmonize at the federal level,” agreed Dr. Torsten Kroger, chief science officer at Intrinsic, an Alphabet unit working on applying AI to make robots easier to use.

U.S. manufacturing overall faces a shortfall of 400,000 roles, growing to 2 million by 2030, he said. None of the major industrial automation providers is based in the U.S., which uses only about 8% of the global supply compared with China‘s 34%, said Kroger.

He recommended that the U.S. lean into its leadership in AI, think about labor perceptions of robotics and AI, and consider safety and intellectual property (IP) security.

Would a national robotics strategy require funding or an office? That’s what the caucus plans to explore with legislators, the administration, and industry stakeholders, A3’s Burnstein told The Robot Report.

“The government currently has many existing workforce programs and incentives at the intersection of AI and robotics,” replied Boston Dynamics’ Schulman. “We want to bring robotics into the AI race, and agencies could even use robotics in their domains to serve people, provide jobs, and develop new weapons. Only the federal government can lead that kind of culture change.”

“Robotics is competing with AI for talent, and once we have a strategy for building robots in the U.S., we then have to collect and use the data to train them,” he added. “China has a five-year strategy, and as a result, it had its first [World Humanoid Robot Games]. The whole industry has to have discussions on specific policies.”

Paul Aiello, executive director of the certified education group at FANUC, pointed out that China has mandated PLC courses in middle school. Any U.S. strategy should not only consider workforce development, but it should also embed robotics and programming into the entire educational system, he said.

“We need a long-term strategy of like 20 years,” Aiello said. “We have to address tariff uncertainty, and policies have to address talent. Every high school engineering program could yield 10 technicians.”

The Congressional Robotics Caucus plans to continue meeting with various stakeholders and making policy recommendations, said Burnstein.

Money isn’t enough to solve U.S. manufacturing problems; a unified robotics policy is needed, said Heather Carroll, chief revenue officer of Path Robotics. Credit: Eugene Demaitre

Responses