Bedrock Robotics announces autonomous excavation milestone

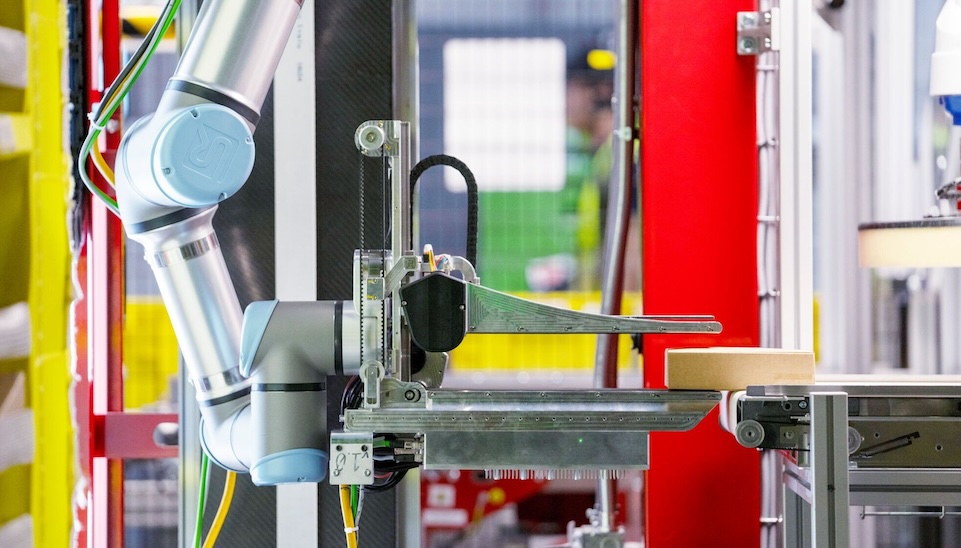

Large excavators are autonomously removing dirt on construction sites. | Credit: Bedrock Robotics

Bedrock Robotics LLC, which has developed autonomy for excavators, demonstrated the capabilities of its technology with partner Sundt Construction Inc. on the set preparation of a 130-acre (52.6 ha) manufacturing facility.

On this project alone, Bedrock’s systems have so far moved over 65,000 cubic yards (49, 696 cubic m) by loading human-operated, articulating dump trucks using the same workflow employed in manual operations. This integration represents a leap forward in commercial autonomous construction, said the companies.

“The biggest challenge we face isn’t just finding operators; it’s keeping experienced ones engaged when we need them for months of repetitive earthmoving in remote locations,” said Dan Green, project manager at Sundt Construction.

“Our best operators aren’t interested in the monotony of mass excavation work,” he added. “With Bedrock’s technology handling the repetitive truck loading that goes on day after day, our skilled workforce can focus on more specialized and creative problems where their expertise is critical to success.”

Bedrock Robotics rapidly iterates for Operator AI

Bedrock Robotics’ core technology is the Bedrock Operator, an AI controller trained to operate the excavator. The San Francisco company has also integrated it with excavator models ranging from 20-ton to 80-ton machines, across a number of the leading heavy equipment manufacturers.

Since its founding in 2024, Bedrock has rapidly iterated on its product. The company went from initial simulation to integrating its first machine (named “Fred”) in just four to five months. By November 2024, Bedrock was testing autonomy on a real site, and it continuously improved its models by collecting real-world data.

The leadership team at Bedrock includes several alumni of autonomous vehicle developer Waymo. Co-founder and CEO Boris Sofman led autonomous trucking and core technologies for Waymo’s public robotaxi network. Other Bedrock co-founders include Kevin Peterson, Ajay Gummalla, and Matthieu Guilbert, all of whom were with Sofman at Waymo.

Sofman told The Robot Report that “a key part of [the development at Bedrock] was a really aggressive shift from the traditional robotics approaches of search and heuristics and these engineered solutions to aggressively embracing machine learning and data-driven approaches to basically capture from math scale data how you solve this infinitely complex problem.”

How did Bedrock develop its product and pivot so quickly?

“We did not have engineers writing software to explain how to operate this machine,” Sofman explained. “We have huge amounts of data, and we have engineers thinking about how to manipulate the data sets and the cost functions and evaluation schemes, and how to structure the problem and manage these large-scale models.”

The evolution of large language models (LLMs) parallels the development of artificial intelligence for robotics, noted Sofman.

“In the same way that an LLM spits out tokens of words … we’re spitting out a trajectory for a high-dimensional machine and body,” he said. “We’re effectively learning from how to emulate the best operators.”

Sensors are mounted above the driver’s cab to provide visibility to the excavator’s work envelope. | Credit: Bedrock Robotics

Partnerships keep safety paramount

Safety remains essential to the deployment of robotics for the real world, especially with large industrial equipment like excavators. In order to better understand the construction market, Bedrock has continued to expand its network of industry collaborators, welcoming Austin Bridge & Road, Maverick Constructors, and Haydon Companies.

These companies join an existing ecosystem that includes Zachry Construction, Sundt Construction, Champion Site Prep, and Capitol Aggregates. Bedrock said its partners help to accelerate the adoption of autonomy across commercial, industrial, and heavy civil applications while ensuring the technology is developed with visibility into the full spectrum of construction scenarios that contractors face daily.

“Safety is at the heart of all we do, and technology has the potential to further enhance the safe performance of work at our job sites,” said Bill Heathcott, executive vice president at Austin Bridge & Road. “Our partnership with Bedrock Robotics has opened the door to autonomous equipment, a game-changer in next-level worker protection, as well as increased efficiency and precision. Together, we’re exploring how this innovation could change construction for the better, help to solve critical skilled-labor shortages, and ultimately allow our crews to get more done.”