igus designs ReBeLMove modular mobile robot, new energy chain

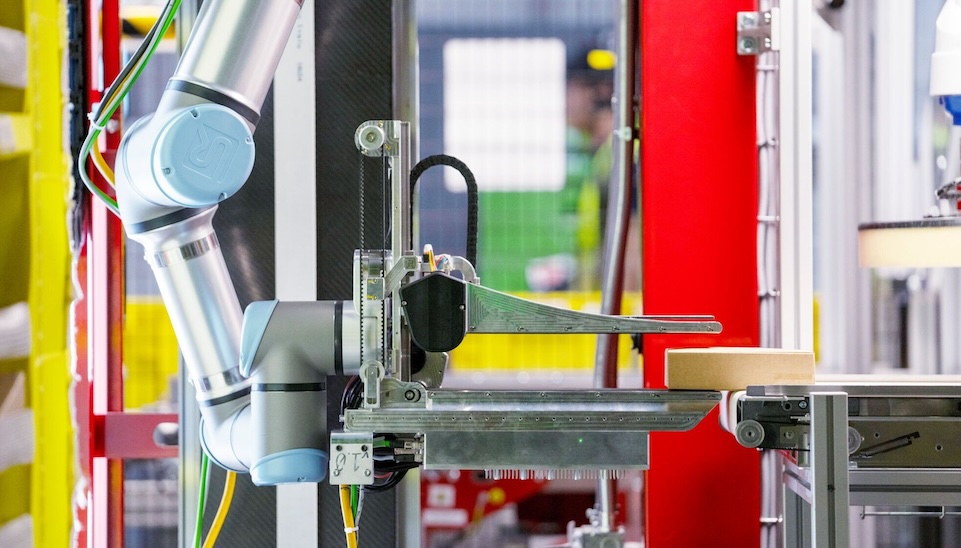

The ReBeLMove Pro acts as a versatile base for multiple add-ons, including order-picking systems, smart shelving units, and collaborative robots equipped with conveyor belts. | Source: igus

Businesses of all sizes need automation that they can easily integrate into existing processes without previous robotics experience, according to igus GmbH. Last month, it launched the ReBeLMove Pro, which it said can be customized for a range of applications. The company is using the modular autonomous mobile robot, or AMR, in its own operations.

“igus itself is already using the ReBeLMove Pro as a shuttle to transport products away from injection-molding machines in production,” stated Sebastian Thorwarth-Kienbaum, a low-cost automation expert at igus. “These are tedious, routine tasks in material handling that companies find difficult to get people excited about.”

igus develops and produces motion plastics. The Cologne, Germany-based company said its self-lubricating, high-performance polymers can reduce costs. igus claimed that it is the global market leader in energy supplies, highly flexible cables, plain and linear bearings, and lead-screw technology made of tribo-polymers.

ReBeLMove Pro is adaptable to multiple tasks

The ReBeLMove Pro is based on a compact, rectangular transport platform on four wheels with an electric drive. The new robot is 795 mm long, 560 mm wide, and 195 mm high (31.2 x 22 x 7.6 in.); weighs 60 kg (132.2 lb.); and is painted black with orange accents typical of igus.

The AMR can navigate autonomously at a speed of up to 2m/s (4.4 mph) and carry up to 250 kg (551.1 lb.) or pull up to 900 kg (1,984.1 lb.). One battery charge is enough for a full eight hour shift, said the company.

By adding attachments to the ReBeLMove Pro, users can adapt it to different material handling tasks. Examples include height-adjustable conveyor belts and an articulated cobot arm for assembly workstations, a trailer for transporting materials, or a shelf with light signals for more productive order picking. The new robot can also be used outdoors.

AMR promises rapid integration, ROI

Savings extend beyond purchase price to integration and return on investment (ROI), said igus.

“System integrators and software licenses often cause high follow-up costs, which lead to companies putting the topic of automation on ice again in frustration,” said Thorwarth-Kienbaum. “We have therefore made a point of ensuring that the ReBeLMove Pro can be integrated and operated without outside help or automation experience.”

During a simple round trip, the robot creates a digital map using lidar, 3D sensors, and a RealSense camera—mapping 200 m² (2,152.7 sq. ft.) in under three minutes. Users can set up movements in 15 minutes without coding skills, said igus.

The ReBeLMove Pro integrates with IT systems via open interfaces — IoT, VDA 5050, REST, SAP, ERP — and it works with fleet management tools like Fleetexecuter, Kinexon, and Naise.

“Thanks to the low investment costs and uncomplicated commissioning and operation, the average return on investment for a ReBeLMove Pro is 12 months,” Thorwarth-Kienbaum said. “The ReBeLMove Pro costs only €38,900 [about $45,238 U.S.], around 25% less than standard market solutions, which generally start at €50,000 [$58,147], without compromising on functionality.”

igus builds energy chain for compact spaces

igus also recently launched a one-piece, injection-molded energy chain in its E1 series. The company said the latest offering provides a simplified and more reliable cable management solution for highly compact spaces.

“We received positive feedback from designers around the world who have been searching in vain for a cost-effective cable guide solution for compact installation spaces,” said Kira Weller, product manager for e-chains at igus.

Designers often skip cable guides in small installations, such as in food vending machines, laboratory equipment, or electric doors. This risks cable damage and can increase maintenance costs, asserted igus.

Made from a single piece of high-performance plastic, the E1 chain is more cost-effective than traditional assembled chains, the company claimed. igus said its easy-chain principle allows users to push individual cables through flexible teeth without tools, securing them and defining a controlled bend radius. This protects cables from chafing, kinking, and breaking, ensuring a longer system service life, it said.

To accelerate its transition to high-volume production, igus is actively seeking design engineers for pilot projects. The company aims to collaborate with users to adapt the e-chain for various applications, including those with extremely short movements of only 40 mm (1.5 in.).

igus said its e-chain cable carriers are more durable than other plastic carriers. | Source: igus

igus innovates and expands with sustainability in mind

igus is represented in 35 countries and employs 4,600 people across the globe. In 2023, it generated a turnover of €1.136 billion ($1.3 billion). The company offers more than 234,000 items in stock through its Configurator, and their service lives can be calculated online.

In recent years, the family-run company has expanded by creating internal startups for technologies such as ball bearings, robot drives, 3D printing, “smart plastics,” and the RBTX platform for lean robotics. The “chainge” initiative at igus recycles used e-chains and supports a company that produces oil from plastic waste.

Last month, igus’ U.S. subsidiary celebrated its 40th anniversary of operations by planting 40 trees at Glenlyon Park and Kimberly Ann Rock Field in East Providence, R.I. The company has expanded U.S. production of its drylin lead screw line and linear bearing assemblies by adding 100,000 sq. ft. (9,290.3 sq. m) to its existing 350,000 sq. ft. (32,516 sq. m) of space in Rumford, R.I.

“With thoughtful planning for cost efficiency and our general philosophy, we saved 27 metric tons of carbon dioxide, or as much as 1,300 cars, by renovating buildings from the 1950s rather than building new ones,” Felix Brockmeyer, CEO of igus Inc., told The Robot Report. “We’re committed to domestic manufacturing and innovation for shorter lead times, improved responsiveness to customer demands, and risk mitigation.”