Inbolt provides vision guidance in real time for new bin-picking system

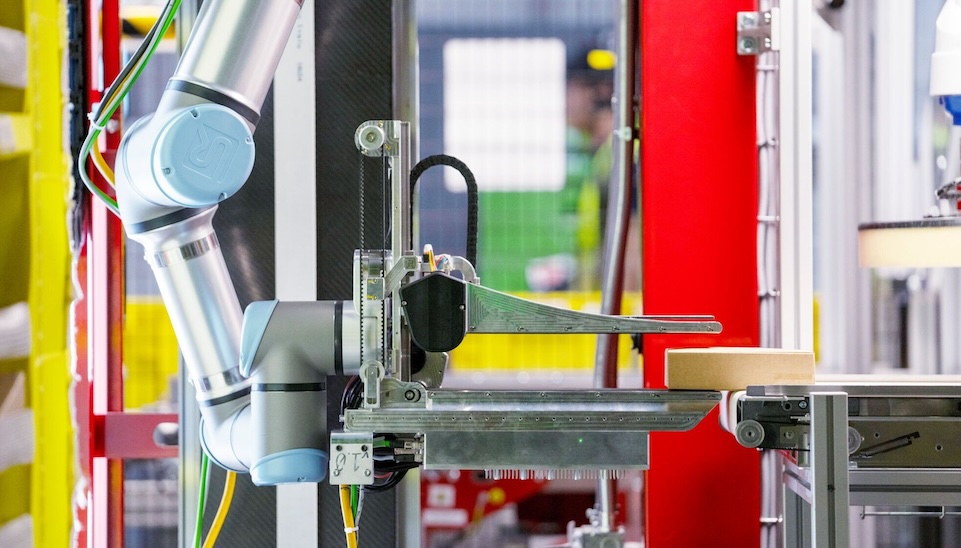

Inbolt moves vision to the robot arm and uses proprietary AI for real-time guidance. Credit: Adrien Boscher, Inbolt

For robots to be useful in unstructured environments, they need fast perception and flexible intelligence. Inbolt has proven its vision-guidance technology and has launched its next-generation bin-picking system, which it said brings “human-like adaptability to industrial robotics.”

The new system enables robots to accurately identify, grasp, and place parts, even when objects are randomly positioned or partially hidden, said the Paris-based company, which recently joined the French Tech 2030 Program.

“Traditional bin-picking systems are too rigid for real factory conditions,” stated Albane Dersy, co-founder and chief operating officer of Inbolt. “We designed our solution to adapt in real time, able to see, grasp, and adjust the way a human would. That level of flexibility is what manufacturers need to reach truly autonomous production.”

Inbolt combines real-time 3D vision and proprietary models to deliver precise part localization and robot control. The company claimed that its generalist AI model “enables any robot to master any process, part, or station, helping manufacturers deploy faster, cut costs, and keep production moving.”

Inbolt gets up close to spot bin picking

Traditional bin-picking systems rely on fixed, overhead high-end and long-range 3D cameras, complex calibration, and pre-calculated grasp points, noted Inbolt. These systems are expensive, rigid, and easily disrupted when bins move, parts aren’t detected, or pre-defined pick points are not accessible.

“Lighting can also be an issue,” Dersy told The Robot Report. “We’ve partnered with RealSense, and our light-agnostic vision guidance provides high reliability on the edge for parts picking on continuously moving lines, such as in automotive.”

Inbolt brings the sensing closer to the objects being handled. With a 3D camera mounted directly on the robot arm and the company’s proprietary AI, the system can continually perceive, understand, and adapt in real time, it said.

The on-arm camera architecture eliminates the need for multiple fixed cameras and expensive high-resolution setups, the company asserted. Manufacturers can deploy the same robot across different bins and configurations, significantly lowering hardware costs and setup time, it said.

Physical AI makes continual adjustments

Inbolt said its AI delivers an infinite number of grasp strategies, so it does not need a perfect grasp. This provides a faster and cheaper solution that takes less than 1 second per pick, with up to 95% success rates in live production, it said.

“With VLAs [vision-language-action models], you’re reinventing the grasp each time,” observed Dersy. “With better data, we have more flexibility. Our system doesn’t locate in the bin; it finds the flat surface.”

Inbolt said its new bin-picking system follows a process inspired by human behavior. It first identifies an object’s pickable sides. Once the object is grasped, the robot analyzes and locates it.

The company’s AI continuously refines the robot’s trajectory for accurate placement with a capability known as “in-hand localization.” Inbolt said this closed-loop process allows the robot to adapt instantly to part variability.

The system runs on NVIDIA’s hardware and uses Inbolt’s proprietary AI robot guidance models, which enable real-time pose estimation and continuous trajectory correction. “This unique architecture minimizes computational load while maximizing robustness, ensuring consistent performance across different use cases and part geometries,” said Inbolt.

“With the latest GPUs, we’re future-proof. We didn’t even use them until about a month ago; we used standard PCs,” Dersy said.

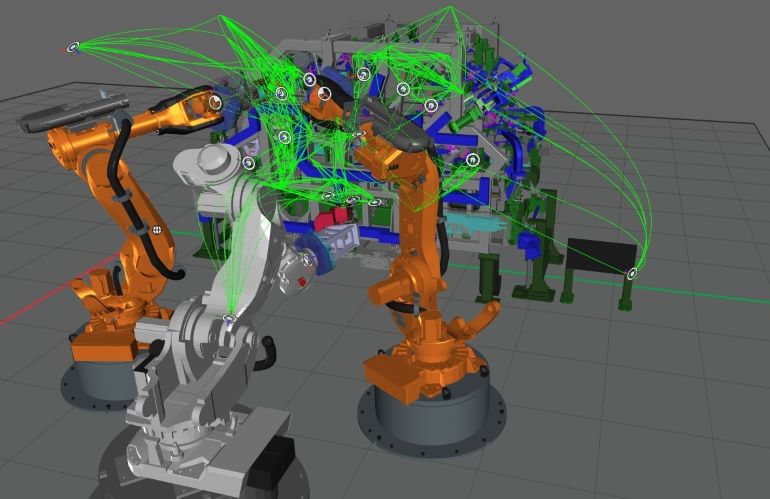

Inbolt has designed its bin-picking system to work with multiple robots. Source: Inbolt

Robot arms can be trained quickly on CAD models

The pose-estimation technology can be trained on CAD models in minutes and is compatible with robots from FANUC, ABB, KUKA, Yaskawa, and Universal Robots. It also works with bins of any size or position, even if they move during operation. Inbolt said this is what make its offering unique in the market.

Founded in 2019, Inbolt won a 2023 RBR50 innovation award for its launch of GuideNow, a self-contained 3D vision servoing and real-time vision guidance system. The company raised $17 million in Series A funding in 2024 and has a U.S. office at the Newlab innovation center in Detroit.

Inbolt rolls out proven tech across facilities

“Factories are semi-structured environments, and our early adopters include the world’s biggest manufacturers,” said Albane. “They can retrofit body-shop lines with the parts positioning we’ve developed.”

With customers including Stellantis, Toyota, Beko, and Volkswagen, Inbolt said it serves more than 70 factories worldwide. Its robots have run 20 million cycles in the first half of 2025 and have demonstrated a six-month return on investment (ROI).

Inbolt’s new unstructured bin-picking system is already running across more than five factories. The company said its technology has consistently delivered high uptime and throughput, proving its robustness in real-world industrial conditions.

Manufacturers looking to modernize their bin-picking stations can request a live demo or a pilot deployment from Inbolt.

Responses