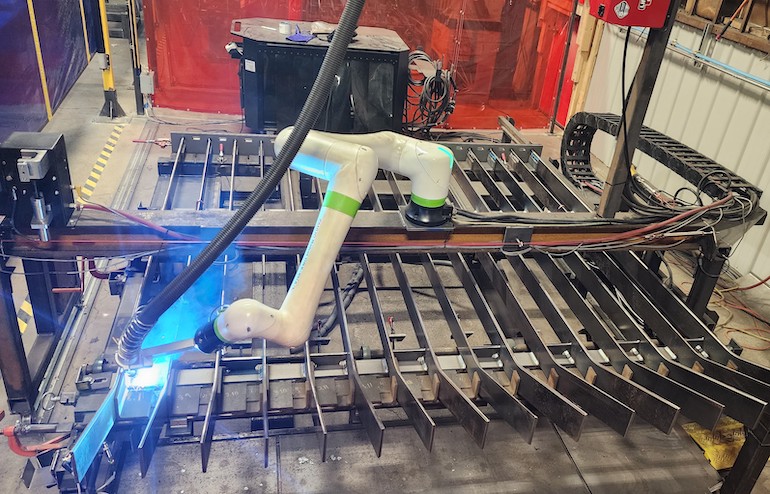

Universal Robots designs UR8 Long for space-constrained tasks

The new UR8 Long cobot can reach farther than its predecessors to automate more welding tasks. Source: Universal Robots

Collaborative robot arms are continuing to grow in size and capability. Universal Robots A/S today announced the UR8 Long cobot, which it is showing at FABTECH this week in Chicago.

“The long-reach industrial collaborative robot is designed to tackle the most demanding automation challenges across industries,” said the company. The UR8 Long is now available for order, and Universal Robots (UR) said it expects to begin shipping in October.

”The UR8 Long is a smart robotic arm that can reach farther and do more than ever before,” stated Jean Pierre Hathout, president of Universal Robots (UR). “It’s designed to help people and businesses work faster, more safely, and with less physical effort.”

“Whether it’s lifting, moving, or handling tasks that are repetitive or hard on the body, this robot makes the job easier,” he added. “Its longer reach means it can cover more space, and its advanced features open new ways to automate work that used to be done by hand.”

UR said it has sold more than 100,000 cobots worldwide. The Odense, Denmark-based unit of Teradyne Robotics noted that its user-friendly platforms are supported by the PolyScope software and its extensive partner ecosystem. Last week, Ujjwal Kumar stepped down as president of Teradyne Robotics.

UR8 Long sports a slim profile, advanced motion technology

With the same 1,750 mm (68.9 in.) reach as the UR20 model and a significantly slimmer profile, the UR8 Long combines reach, stability and precision in a rugged, compact, lightweight form, asserted Universal Robots. The new cobot has a payload capacity of 8 kg (17.6 lb.), which the company said makes it suitable for space-constrained setups and industrial tasks, from complex weldments to precision dunnage picking and flexible multi-point inspections.

UR8 Long runs with both PolyScope 5 and PolyScope X software It can be extended with MotionPlus, UR’s new motion control technology that allows for ease of integration with linear axis, rotary positioners, and rotary turntables for precise control, smoother trajectories, and consistent accuracy.

Universal Robots claimed that its upgraded freedrive capabilities allows users to manually guide the arm with precision and ease, making programming more intuitive and enabling fast setup without the need for layered interfaces or external tools. The UR8 Long has 30% less mass than the UR20 force- and power-limited robot arm.

In addition, UR said the new robot’s compact wrist design means that it can be mounted on gantries, rails, or overhead systems, where external axes can operate more efficiently.

With advanced motion control, the UR8 Long can conduct automotive quality inspection. Source: Universal Robots

Universal Robots designs for welding applications

With its long reach, advanced motion control, and precision and repeatability, UR8 Long is ideal for welding, said Universal Robots

“UR8 Long delivers an easier teaching experience than traditional welding robots, better weld quality than manual welding, and less overall rework, saving time and money,” said Will Healy III, global industry manager for fabricated metals at Teradyne Robotics. “Following feedback from fabricators around the world, the UR8 Long was designed with the collaborative welding process in mind, boosting productivity and helping leaders to attract new talent who are often more motivated to operate a robot than perform repetitive manual welding.”

FABTECH attendees can see the UR Long in welding demonstrations at several UR partner booths, including THG Automation, Hirebotics, and Vectis Automation.

“The improved features of the UR8 Long enables expansion into new welding and plasma cutting applications, all without sacrificing safety or man-machine collaboration,” said Marcus Yakawich, product banager at Vectis Automation. “We can’t wait to share these long-reach advantages with our customers.”

UR partners will demonstrate the UR8 Long at upcoming events. Source: Universal Robots

UR cobot also reaches into bin picking

At its own FABTECH Booth B13045, Universal Robots will demonstrate the UR8 Long’s reach into a full dunnage bin, commonly used in automotive, metals, plastics, and other manufacturing applications.

“The longer reach, combined with the new robot’s compact tool flange and fast wrist joints, allow more pick positions and for the robot to reach deep into bin corners with ease,” said UR. In the automotive industry, the UR8 Long can easily integrate into space-constrained cells and offer more picks per bin and more uninterrupted workflows, it said.

The improved joint architecture delivers up to 30% faster cycle times compared to earlier generations of cobots, added the company.

UR8 Long will debut in Europe next week at SCHWEISSEN & SCHNEIDEN in Essen, Germany. Universal Robots partner Smooth Robotics will show the new cobot in its booth, and Lorch Schweißtechnik GmbH will demonstrate UR8 Long in Hall 3 at UR Stand 3C18. Universal Robots will also present UR8 Long at 11:30 a.m. on Sept. 18 on the Future Hub stage.